Luiz transports his sugar cane to a factory, where it’s made into molasses. But things aren’t going well: profits are down, and costs are sky high – and he’s pulling his hair out.

There goes my holiday in Hawaii!

Plattformen kan ha en startsida.

Här kan man lägga välkomnande text.

Ofta fungerar startsidan också som meny där man kan nå övriga sidor.

Har man ingen startsida hamnar man direkt på "sida 1".

The world

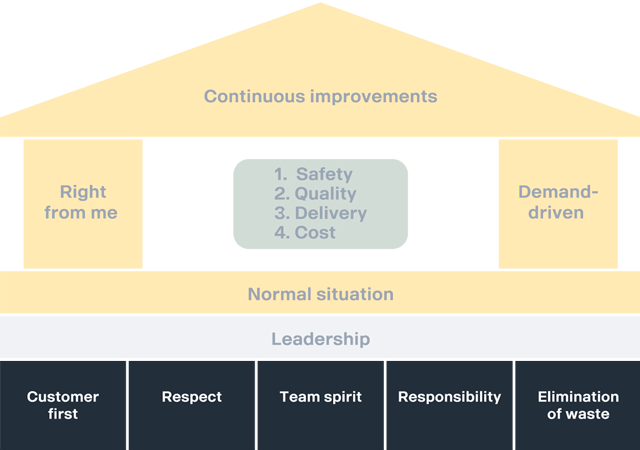

The Scania Way

Together

The

This

We

Want

Want

What

This

Want

Want

This

We

Want

Want

This

We

Want

Want

Good

Good

Good

Our

–

–

–

Good

Our

Click

Customer

Respect

Team spirit

Responsibility

Elimination of waste

Our

We

We

Want

Want

Our

The core

We

Why do we have core values? Watch this film to find out more.

Why do we have core values? Watch this film to find out more.

We

We

Respect

Want

Want

Our

The core

We

Why do we have core values? Watch this film to find out more.

Why do we have core values? Watch this film to find out more.

We

We

A

Want

Want

Our

The core

We

Why do we have core values? Watch this film to find out more.

Why do we have core values? Watch this film to find out more.

We

We

We

Want

Want

Our

The core

We

Why do we have core values? Watch this film to find out more.

Why do we have core values? Watch this film to find out more.

We

With

We

Want

Want

Our

The core

We

Why do we have core values? Watch this film to find out more.

Why do we have core values? Watch this film to find out more.

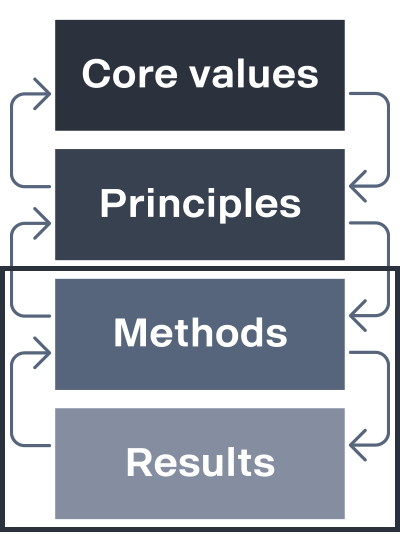

The Thinking Model outlines our way of thinking and doing things when it comes to solving problems and achieving results.

Click the boxes and the highlighted arrows for more information.

Is it

Is it

This is the story of how Fernanda uses the Scania Way to help Luiz turn his sugar cane business into a profitable success.

Luiz transports his sugar cane to a factory, where it’s made into molasses. But things aren’t going well: profits are down, and costs are sky high – and he’s pulling his hair out.

There goes my holiday in Hawaii!

Luiz tells Fernanda all about his problems – as he sees them.

20% of my sugar cane is going bad before it reaches the factory.

I just don’t have enough trucks. I’ve got ten but I’ll have to buy two more. Otherwise, even more sugar cane will go bad!

Fernanda listens to Luiz and concludes that the main problem is…

Choose your answer!

It’s time to understand Luiz’s current situation and find out what’s going on.

It’s clear Luiz faces a lot of challenges. But Fernanda focuses on the why. She asks herself these questions.

How can I help Luiz?

What’s the situation like now?

Why is transport such a big problem?

Why is transport so expensive?

Why is the sugar cane rotting before it gets to the factory?

I’ll take care of all your logistics.

The purpose of any solutions I come up with is to reduce your costs.

Both your company and mine will make a profit.

Fernanda knows she has to see what the problem is for herself. But before she does that, she talks business with Luiz.

Wow! That’s ambitious!

I’ll take care of all your logistics.

The purpose of any solutions I come up with is to reduce your costs.

Both your company and mine will make a profit.

Fernanda has a lot of questions (and an open mind) when she goes to Luiz’s sugar cane fields and the factory that makes the molasses.

She talks to a lot of people… You’ll have to click the headings to find out more!

I’m bored! There’s a really long queue of trucks in front of me. This is going to take forever!

Another tough day at work. Only one of me and ten trucks waiting to be loaded with sugar cane!

A whopping 20% of my sugar cane goes bad before it gets to the factory. Such a shame!

Mondays to Thursdays are easiest. The trucks arrive one by one, and we have time to unload them.

We throw away a lot of the sugar cane – especially on Fridays.

Friday’s a nightmare. The trucks arrive really late, and we have no idea when they are going to come.

DISCUSSION QUESTIONS

If you’re going through this case in a group, then discuss the questions with your group members.

If you’re going through this case on your own, then spend a few minutes reflecting on the questions.

What do you think Luiz’s main problems are?

What are the reasons for these problems?

Fernanda is ready to carry out her analysis and focuses on one problem at a time. She does this in three steps.

Click each number in turn.

Step 1.

Why?

Fernanda asks:

Why are there such long queues when loading the sugar cane?

Hmm…

Step 2.

The root cause

After investigating the situation, she finds the reasons for the long waiting times:

Step 3.

The solution

Fernanda comes up with a solution that doesn’t mean extra costs for Luiz. What is her solution?

Now that the drivers start at different times, there are no longer big queues of trucks waiting to be loaded. Which principle or principles does this solution connect to the most?

Click the principle(s) in the house.

We can’t know everything when we start…

Different starting times for drivers makes loading more effective, but it doesn’t completely solve Luiz’s problem.

There are still truck delays, meaning there is internal variation.

So, what does Fernanda do?

She uses the Thinking Model to look at the results she got.

Then she re-evaluates her methods to get even better results.

This is a good example of a learning loop where we evaluate and test until we get the results we want.

Thanks to the Thinking Model, Fernanda comes up with two more solutions to reduce truck delays:

Fernanda now turns her attention to the second problem. She follows the same three steps as before.

Click each number in turn.

Step 1.

Why?

Fernanda asks:

Why is 20% of the sugar cane going bad before it gets to the factory?

Step 2.

The root cause

It takes Fernanda a while, but she discovers two main reasons for the rotting sugar cane:

Step 3.

The solution

What solution do you think Fernanda comes up with?

Fernanda’s solution to avoid driving during the rush hour on Fridays reduces the unpredictable and often late arrival of the trucks at the factory. Which principle or principles does this solution connect to the most?

Click the principle(s) in the house.

The Scania Way is now in place and Fernanda’s solutions are good for the customer – and good for us as a company.

We cannot improve without committed employees and that means we need the right leadership in place.

Fernanda has included everyone in the process, boosting engagement, an improved way of working and, above all, better well-being and performance.

This is a good example of how Fernanda worked according to our core values, especially respect for the individual.

Fernanda and Scania are responsible for the drivers and trucks – and at a lower cost than before!

This means Luiz can focus on his business and not worry about anything else. And he has more money in his pocket!

Everything works more smoothly – and the drivers and factory workers no longer feel frustrated. What’s more, we make a profit. It’s a win-win situation.

Luiz is happier, has more time on his hands and his profits are up.

So yes – he got his holiday in Hawaii (and his hair is looking much better too)!

DISCUSSION QUESTIONS

If you’re going through this case in a group, then discuss the questions with your group members.

If you’re going through this case on your own, then spend a few minutes reflecting on the questions.

How can you go from good to great where you work?

What can you improve?

And how can you work better when it comes to problem solving?

Want to

Now it’s

Discuss

Be as

Do you

Get into

If you don’t have a standardised way of working, then you might want to stop here. You and your team probably need to focus on finding a shared way of working. Skip to Summary

If you

Get into

You don’t

Thomas

You know

A big

The Scania

You learn